Overview of Laser Engraving on Metal

We proudly offer personalized engraving to make our handmade leather items uniquely yours. Please note:

Engraving is Only for Our Products: This option is exclusively available for leather items purchased from our store. We do not engrave items bought elsewhere or customer-supplied items.

We all enjoy beautiful patterns and text on metal keychains, jewelry, utensils, pet accessories, etc., however, not all of us may be familiar with how these outlines and letterings appeared on metal and what this process is called.

Engraving is a popular way to add a special accent to products, brand them, and turn them into meaningful gifts that carry a lot of sense to the recipient. The art of engraving originated centuries ago, and this finishing method was very popular for the manufacture of weapons, tableware, and jewelry. At those times, not everyone could afford engraving, and only wealthy people could enjoy the beauty of uniquely engraved goods. Luckily, modern technologies have enabled quick, effortless, quality, and most importantly, affordable engraving. Our workshop has been offering engraving on stainless steel and leather for years, and I'd like to tell you about this method of personalization on metal in more detail.

In this article, we're going to discuss the definition of metal engraving, types of metal that are suitable for engraving, how to engrave metal to prevent it from cracking and chipping, types of engraving, what metal and engraving method Hidemont prefers for complementing leather accessories, and some laser engraving ideas for your new designer pet nameplate or ID tag.

What Is Metal Engraving

To put it simply, engraving is the process of lettering, picture, pattern, and text marking on metal of a certain shape and size. Engraving is becoming increasingly popular because it's the easiest, most advanced way to make any item unique, individualized, and meaningful. This graphic technique enhances the appearance of most materials like glass, wood, plastic, textile, leather, ceramic, and marble, too. Here is more information about engraving on leather. Besides, engraving serves not only for aesthetic purposes but identification and branding, as well. Most of the top companies engrave their goods with logos to make them recognizable across the globe.

What Kind Of Metal Can Be Engraved?

Many metals are suitable for engraving but it's essential to mention that different metals behave differently when being engraved due to their unique natural properties. Aluminum is a soft versatile metal that is easily engraved so all the carved lines, letters, numbers, and other little details stand out on the metal surface. Even though it's the most common manufacturers' choice, there's still a diversity of metal alternatives that look beautiful when engraved.

Engraving on gold and silver

These are delicate metals mostly used in the jewelry industry. The natural properties of these metals allow making deep cuts so that the engraving is quite sustainable and the special saying on it will last longer. Engraved golden and silver necklaces, rings, or bracelets are perfect keepsake gifts that will bear some extra romantic value and be cherished for years.

Engraving on brass

Brass is one more pliant metal that has a special golden-like coloring with a more distinctive rustic finish. This metal is commonly used for plumbing system components, musical instrument parts, gears, locks and door handles, belt buckles, and for sure, sometimes, the need of decorating brass items may appear. However, this metal isn't engraved as effectively as, for example, gold and silver, and neither laser engraving, nor rotary engraving work great for this metal engraving. In terms of laser engraving, the rustic finish reflects the beams, so that the laser-engraved text is illegible, semi-transparent, and dull. Furthermore, rotary engraving will look the best on brass items only with text or patterns of considerable size and line thickness. The smaller or thinner markings should be made on brass, the more chance that the result won't meet the expectations.

Engraving on steel and stainless steel

It's widely known that to engrave steel, one should have special equipment and expertise because this material isn't easy to be engraved. Before I started to offer the option of metal personalization, I conducted a considerable study on engraving on steel and other metals, on how to engrave steel, and in particular how to engrave stainless steel, so that it doesn't crack or chip during the process, as well as on what is the best laser engraver stainless steel machine.

For my leather accessories production, I prefer stainless steel engraving. First of all, stainless steel is solid, durable metal, and its natural rigidness prevents it from cracking and chipping during the engraving process. Also, the metal texture allows one to engrave steel with no effort and ensures deep laser engraving so that the markings won't scratch out over time. Second of all, stainless steel is non-toxic metal, resistant to corrosion and moisture, which guarantees long-lasting quality and attractive appearance.

Types Of Metal Engraving Methods

Depending on the equipment and tools used during the process, there are two main types of engraving – rotary and laser engraving.

Rotary engraving involves the direct interaction of a spinning cutter with metal. The cutter moves through the metal surface, cutting out its outer layer with the predetermined depth and creating a shallow relief carving on the surface. This method is also known as “notching”.

In the video above, water drops fulfill three functions – cooling of metal surface, prevention of spinner cutter wear-and-tear, and reduction of metal micro dust spreading

In contrast, laser engraving presupposes the lettering, pattern, or text incising with the help of a focused, software-driven laser beam, and there's no direct interaction between the laser and metal.

During the procedure, the laser beam heats the metal surface, burning, vaporizing the microscopic outer metal layer and creating the carving invisible to the naked eye. The place where the laser beam passed and where the carving appeared, is distinguished by a darkened color, which, as a result, forms the desired text or picture. The beam is narrow-focused, the exposure area is quite small, and the change in metal structure is insignificant, which excludes the risk of material damage, and the appearance of chips, scratches, and cracks. Deep laser engraving is preferred by manufacturers because it eliminates the chance of product spoilage and is the best method to process engraving on steel and aluminum – the most common metals.

Comparing two different methods, it's necessary to state that both are thought to be highly-advanced ways of engraving not only on metal but a wide variety of materials as well commonly used in contemporary manufacturing. Yet, they're quite different in the way they operate and the result they produce. If you're a newbie to the industry of engraving, you should consider the following pros and cons of both methods.

Rotary engraving

|

Cons |

Pros |

|

|

|

|

|

|

|

|

Laser Engraving

|

Cons |

Pros |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What Does Hidemont Use Laser Engraving For

Hidemont provides quick and quality stainless steel engraving on nameplates and ID tags (learn more what's the difference between silent nameplates and ID tags). These are mostly used for leather accessories for dogs and leather accessories for cats.

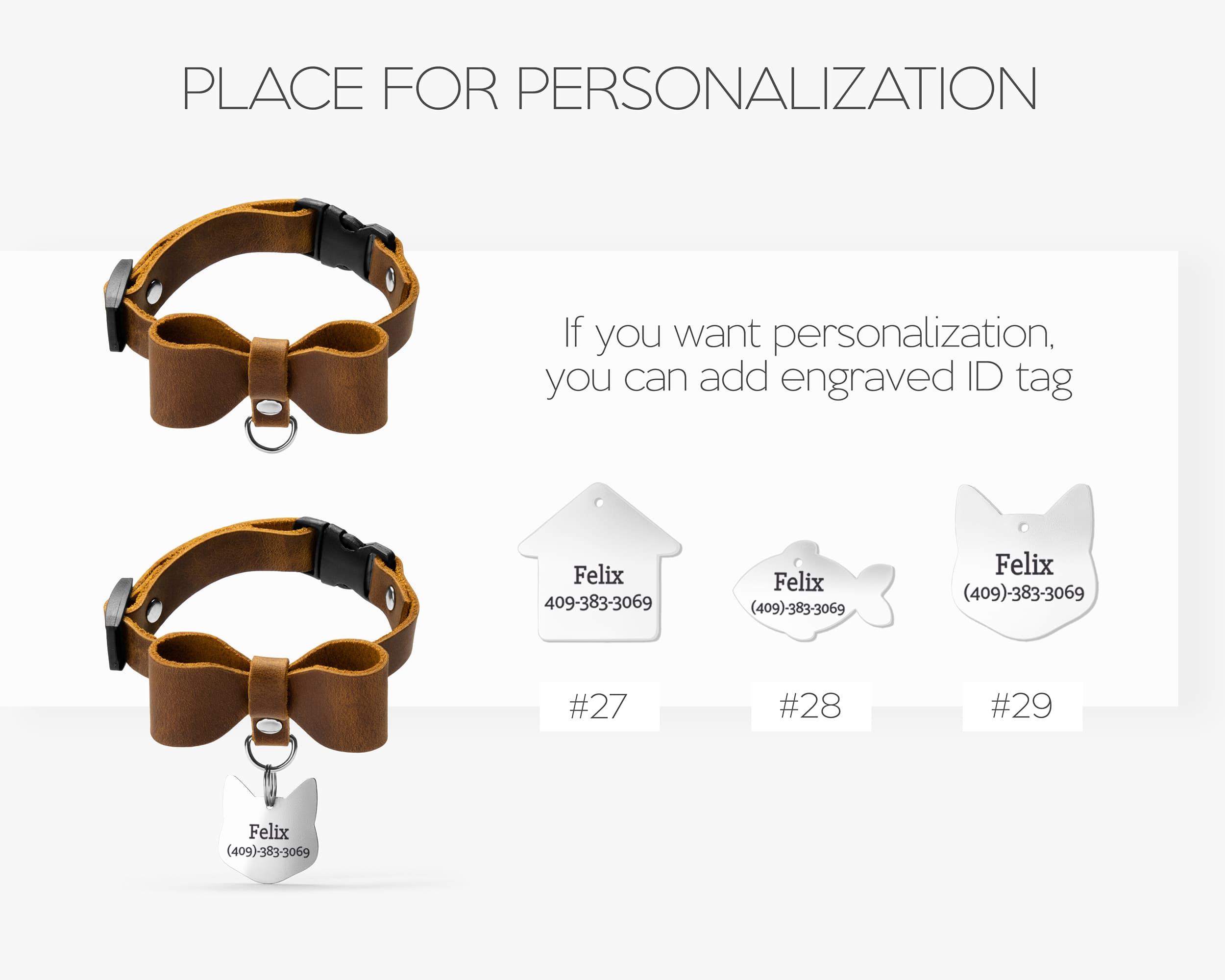

Shopping with Hidemont, you can personalize leather collars for dogs with a custom engraved silent nameplate available in cute designs.

Add a special touch to your kitty's daily look, by getting leather collars with a belt buckle complemented with a laser-engraved silent stainless steel nameplate or bowtie leather breakaway collars finished with laser-engraved ID tags.

Custom laser engraving is the best way to give a unique accent to your pet's look and extra security for enthusiastic escape artists. If you're looking for some laser engraving ideas to pamper your pet with a new fashionable and secure accessory, consider our simple recommendations. Pet nameplates and ID tags can be engraved with vital details like a dog's or cat's name, your phone number, or microchipping information.

When choosing pet collars, you should take into account not only the quality of material and hardware, safe and comfortable design, and cute appearance, but the method of personalization as well. And, stainless steel engraving is the best option for you to plump for. Here are some more tips about how to choose a dog collar and a cat collar.

We know that sometimes our little friends can be too curious, sniffing and exploring everywhere, sneaking around sharp branches or furniture corners. If you choose cheap pet ID tags, it may result in tag damage and text scratching out. Unlike mass-market poor-quality metal or plastic ID tags with printed rather than engraved personalized text, Hidemont nameplates and ID tags are laser-engraved to ensure the text doesn't fade over time or scratch out. Besides, the technology of laser engraving allows to mark a small text (if needed to fit all the information) that will look completely legible and precise on the stainless steel nameplate or ID tag.

To Sum Up

Engraving is the quickest, most popular, and most advanced way to make any metal product more distinctive, personal, and memorable. Customized metal accessories make lovely gifts for her and him that will give deep emotions to be engraved on your special ones' memory. Most items, made of diverse metals, can be customized with engraved letters, numbers, pictures, and texts but it should be taken into account that, on different metals, the engraving looks not the same.

At times of rapid technologies and industry development, both rotary and laser engraving methods are in growing demand. Each method has its pros and cons, and both rotary machinery and laser engraver stainless steel machines operate differently, providing a significant difference in the result. Although, aspects in which laser engraving on steel might be preferred, are quick processing, versatility, sustainability, quality, and attractive appearance.

Hidemont is honored to provide quality stainless steel engraving to make your pets feel loved. Our rich online collection of leather accessories for pets can be personalized with quality, corrosion-resistant stainless steel nameplates and ID tags with custom laser engraving of name, phone number, or microchipping information. Such an effective solution to dog and cat accessories personalization ensures both safety and special, wonderful, and fresh style for your little furry friend.